Global Toolmaking

Prototype Phase

Also known as Pre-production phase, this may involve rapid prototyping of component parts by 3D printing (Additive Manufacture) or vacuum casting for a small batch.

For larger batches of up to 20,000 parts we provide rapid tooling from Aluminum or soft steel which is designed to be as close to production intent as possible.This is a cost effective way of producing functional parts that can be tested to ensure that the part design and tooling method is correct for future high volume manufacture.

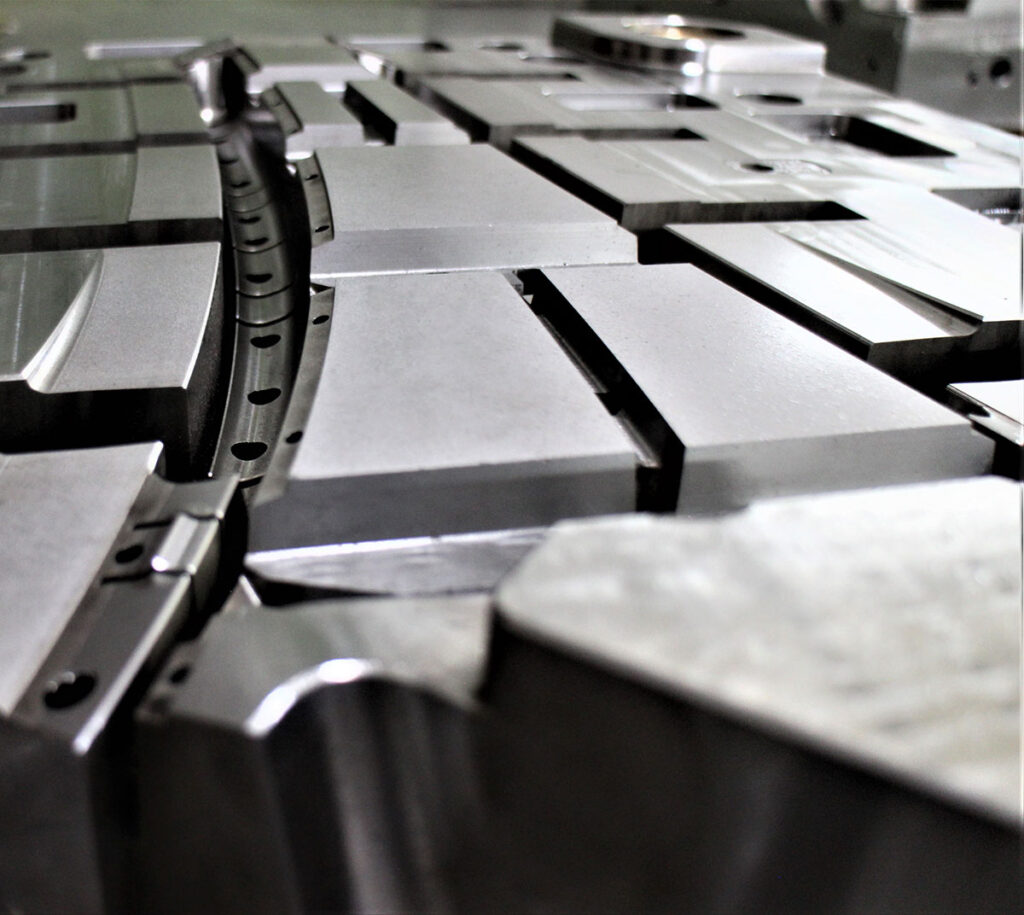

Production tooling

For mass production, we source high precision, high quality injection mould tools for a wide variety of product applications, including Automotive, Aerospace, Medical and consumer products.

Production tools are manufactured from a range of high grade, hard wearing steels that are suitable to the specific requirements. All tools are managed by Liondell from start to finish. At tool design stage we contribute our technical expertise and know-how by providing insight into the needs of the client and to assist the tool designers in achieving a quality tool and product.

Global Warranty Support

Production tooling will include a shot-life warranty which is provided at quotation stage, dependant on the clients specific project requirements.

With our close ties to our main supply base in China and by using established toolmaking partnerships across the UK and other countries, we provide for any warranty and modification services that may arise, wherever our client may have their manufacturing facility.

How to get started

Next steps

1

Call or send us an email with your project requirements.

2

We will acknowledge your inquiry and aim to respond with technical and commercial proposals within 24hrs

3

Our goal is to make our clients happy with the whole process and the results within the agreed timeline.

It starts with a 5-minute introduction call